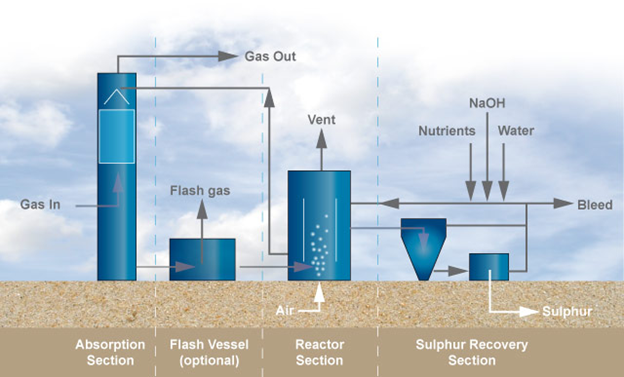

<p style="text-align: justify;">In <strong>thiopaq process</strong>, both sulphur recovery and gas purification processes are integrated into a single unit. First of all, the gas will come in contact with the solution present in the absorber and then absorb H2S leading to the formation of sodium sulphide. The sweet gas will not leave the absorber, and it will then be available for further processing or direct use.</p>

<p style="text-align: justify;">The processes that follow the sulphide-loaded solution are determined by the pressure of the sour feed gas. The gas gets directed to a bioreactor or a flash vessel; the bioreactor operates at ambient temperature and atmospheric pressure. In this chamber, elemental sulphur is formed from the reaction between the sulphur and microorganism. The solution obtained is then passed over the absorber to be re-circulated. Part of the said product is also directed to the sulphur recovery section. This way, the system can be rid of any <strong>elemental sulphur</strong>.</p>

<p style="text-align: justify;"> A decanter centrifuge can then be used to separate the elemental sulphur produced from the solvent. Water is recovered in the process, and it is then recycled via the bioreactor to the thiopaq process. There is a given level of salt that should be accumulated in the system. The salt level is prevented from becoming excessive by bleeding the system using a small slipstream.</p>

<p style="text-align: justify;">In summary, <strong>thiopaq</strong> is more or less a desulphurization process of biogas. The very first commercial unit for this purpose was built in the Netherlands in 1993. The product obtained had been used for several processes in the industrial world since then, and many more units have been built after then. The unit built in 2002 in Canada stands among the first for the commercial process in the natural gas industry. This technology has won the Sellafield award for engineering excellence in 2007.</p>

<p style="text-align: justify;">The entire process involved is environmentally friendly. It is a desulphurization process just perfect for the complete removal of H2S and also for the conversion of the H2S to elemental sulphur using sour gas streams as the raw material. The fact that thiopaq makes use of naturally occurring bacteria to form elemental sulphur from H2S makes this process to be unique. The product formed from the entire process can be used in the production of fertilizer for agricultural processes, amongst other applications.</p>

<p style="text-align: justify;">The first group to market this process for biogas treatment is Paques BV. The biogas used in the process is produced by anaerobic digestion of wastewater. The process stands as one of the best ways to recover sulphur and transform it into several useful products.</p>

<p style="text-align: justify;">The benefits of thiopaq process are numerous. For one, it helps to reduce the need for chemicals that are needed for liquid redox processes, reducing the chemical requirements to nutrients and sodium hydroxide only, thereby reducing operating costs. Also, the process can be easily operated in ambient temperature without requiring reboilers, burners or any other equipment. Since the process involved in the recovery and regeneration of sulphur can be operated under ambient temperature and pressure, then capital expenditure of the process will be highly reduced.</p>

<p style="text-align: justify;">One other thing that makes thiopaq process a suitable process is its ease of operation. The sulphur produced as a result of this biological process is hydrophilic. As a result, plugging process is eliminated, remaining that very little attention will be required from the operator. The process is equally safe.</p>

Outstanding Facts About Thiopaq Process