<p style="text-align: justify;">If you look around, you will find more than fifty percent things around you are made from plastic. Plastic is man-made material, whose roots have crept into every aspect of human life. It is seen everywhere including the stationary, the appliances, switches, furniture, toys, domestic items, vehicle parts, etc., everything consists of plastic. It is an inseparable part of human existence now.</p>

<p style="text-align: justify;">How these things are manufactured using plastic is the question. There are many methods prevalent in the industry but injection molding is the current trend. This is because it is the most efficient way to mold plastic. It has so many benefits that most of the factories employ plastic injection molding services.</p>

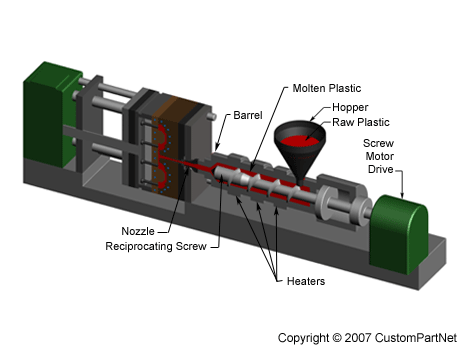

<p style="text-align: justify;">In injection molding the molds are subjected to high pressure, which provides strength and fine details. Machine or molds are used in this technique. This method is much more reliable, simple, time-saver and produces high quality products. There is no need to be skeptical about this procedure.</p>

<p style="text-align: justify;"><img class="aligncenter size-full wp-image-1452" src="http://incrediblemag.com/wp-content/uploads/2015/10/injectionMolding_machine_injection.png" alt="Plastic Injection Molding - Advantages It Offers In Manufacturing Parts" width="467" height="350" /></p>

<h3 style="text-align: justify;"><b>Advantages of Plastic Injection Molding</b></h3>

<p style="text-align: justify;"><b>Ensures intricate features &#8211; </b>The molds are subjected to high pressure, thus detailed and complex designs are also possible. Due to excessive pressure the complex geometry can be recognized otherwise manufacturing intricate details would be a difficult as well as expensive.</p>

<p style="text-align: justify;"><b>Increases strength &#8211; </b>In plastic injection molds it is possible to put fillers in between. This increases the strength of a particular area and reduces the density of the plastic. So in whichever part extra strength is required, fillers can be introduced. It makes the plastic more durable and strong.</p>

<p style="text-align: justify;"><b>Highly Efficient &#8211; </b>This method does not consume much time and is a lot faster. It is also simple. From a single mold multiple products can be manufactured. The high production rate makes it a cost effective method.</p>

<p style="text-align: justify;"><b>Allows usage of multiple plastics &#8211; </b>One of the major advantages of injection molding process allows you to use several kinds of plastics. You can use different types of plastics simultaneously using co-injecting molding. It takes away your worry about using specific plastic type.</p>

<p style="text-align: justify;"><b>Eco friendly and safe &#8211; </b>The plastic materials are molded as per the requirements and can be recycled by melting and injecting them again into different molds. The process is also safe and secure.</p>

<p style="text-align: justify;"><b>Fully automated process &#8211; </b>Plastic injection molding process is fully automated, carried out by machines and robots. Thus it reduces the cost of manual labor and the production gets completed on-time along with the <strong>maintenance</strong> of quality. Automation reduces the overheads and overall cost, which can be passed to consumers.</p>

<p style="text-align: justify;">Overall it can be said that plastic injection molding is very versatile and inexpensive technique that uses computer aided design (CAD) and computer aided manufacturing (CAM) method. It results in producing everyday goods, automotive parts and other supplies with ease.</p>

<p style="text-align: justify;">There is minimal wastage as nothing is left behind in terms of crap or waste. It also ensures that the appearance of the finished product can be viewed, as soon they are taken out of the molds. This environment friendly method is very efficient and effective.</p>

Plastic Injection Molding – Advantages It Offers In Manufacturing Parts