<p style="text-align: justify;">In a wide range of industries, the Silicone rubber act as a primary sealing material that includes electronics, aerospace, medical and automotive and many more. Just to know the wide aspects of Silicone, it is imperative to know the various deals of Silicone that is not only unique but also provides optimal qualities that are often sought after to denote the number of practices. What exactly is Silicone? A clean rubber material that is with low odour and taste, provide a wide variety of benefits that includes the ability to repel water, compression set resistance and insulation from electricity. However, it is necessary to realize the complex technology to manage the production and why silicone is now the most promising industry to furnish, protect and improve our quality of life.</p>

<h4 style="text-align: justify;"><strong>Ability to Sterilize</strong></h4>

<p style="text-align: justify;">According to the FDA regulation, the Silicone rubber is prepared to generate a complete compatible solution, and thus, it undergoes a series of detailed sterilization processes. Among the many practices of sterilizations, there are some methods like steam autoclaving, dry heat, gamma radiation, ethylene oxide and electron beams, and many more to name. Hence, the sterilization processes help Silicone property to be appropriate to use and optimum eligible to use further in varied sectors. Considering the medical industry, the silicone rubber gets through ample number of sterilizations to meet the medical-grade guidelines.</p>

<h4 style="text-align: justify;"><strong>High-Quality Sealing Properties</strong></h4>

<p style="text-align: justify;">Due to the accurate process of silicone injection molding, the Silicone provides an excellent thermal stability to withstand intense high or low temperature. It is capable of retaining flexibility in extreme low-temperature conditions, and proved to be an optimal material to practice any procedure in terms of extreme temperature environments. Moreover, Silicone has the property that can also resist the materials like chemicals, acids, bases, water, oil and fungus. The best part is the quality of the rubber is of optimum and is non-toxic and considered to be the trusted sealing materials for medical platform, construction industry and to make any consumer products.</p>

<h4 style="text-align: justify;"><strong>High-performance capabilities</strong></h4>

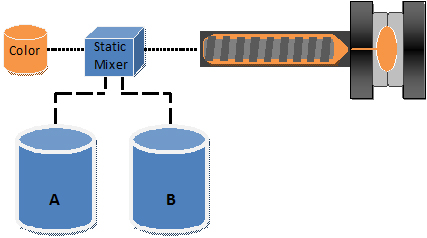

<p style="text-align: justify;">As Silicone is known for the maximum retention of flexibility and low compression properties to withstand intensified cold and heat, the products made up of Silicone is very durable and has got quality mechanical properties. It is also extremely reliable and thus, trusted by the maximum industry to manage their production, performance and service for a long time. Moreover, the <strong>Liquid silicone rubber molding</strong> is an excellent solution that provides high optical clarity, if you need optimum optical clarity of Liquid Silicone Rubber, select the LIM molding, and get durability, freedom design, optical clarity and productivity. Upgrade the feature, and get a unique design that not only illustrates rigidity and flexibility but also, with precise micro-structure.</p>

<h4 style="text-align: justify;"><strong>Versatile Feature</strong></h4>

<p style="text-align: justify;">The properties of Silicone are simple and thus, it is very easy to customize and mold as per requirements and specifications. Crafting according to the unique requirements, adjust the recipe of the compound and obtain the necessary properties, such as extreme temperature and water resistance. You can get it under any colour, translucent feature and even glowing. The versatile feature of the silicone is always the best part that offers a unique benefit, like conductive, self-lubricating, medical-grade, radio-opaque, self-bonding and many more to count.</p>

<p style="text-align: justify;">In everything from textile, to households and aviation, the introduction to Silicone has changed the dynamics of production industries. Enhance the quality of the existing materials and provide a new idea that reinforces innovative properties through silicone injection molding, and render the demand of any industry application.</p>

Unique and Optimal Benefits of Silicone Rubber: An Excellent Material for A Diversified Industrial Application